Product Description

Advantages of 3M™ Double Coated Urethane Foam Tape 4016

- Off-white, 0.0625 in. (1.6 mm) open-cell, flexible urethane foam carrier

- High shear adhesive with high temperature resistance

- Durable foam is ideal for interior mounting applications

- Ideal for bonding, attaching, and mounting

- The foam dampens and prevents vibration

3M™ Double Coated Urethane Foam Tape 4016 is an off-white, 0.0625 in. (1.6 mm) thick, double coated, open cell urethane foam tape that offers high shear strength. It is ideal for applications such as mounting interior signage and nameplates along with soap dispensers and air fresheners.

Versatile Bonding

3M™ Double Coated Urethane Foam Tape 4016 is a 1/16 in. thick tape manufactured with 3M™ Adhesive 100 for a strong, permanent bond that works well with the open cell foam structure to produce high shear strength. This tape offers an ideal solution for a wide selection of bonding issues on various surfaces. This includes both interior and exterior applications where the tape will be protected from the environment.

This tape features a conformable foam and adhesive combination which provides long-term holding at temperatures up to 220°F (104°C). By using a robust, green plaid, densified kraft paper liner, this tape provides you with reliable performance for industrial applications, such as die-cutting and automated dispensers. The liner also helps reduce edge roll and protects the tape from humidity extremes.

Recommended Applications

- General interior and exterior mounting applications where the tape will be protected from the environment

- Mount interior signs and nameplates

- Mounting dispensers and air fresheners

- Bond acoustic panels to walls

- Attach wire clips to wall surfaces

- Mount corner protectors

Enduring Bond

3M™ Adhesive 100 is a firm, acrylic, pressure sensitive adhesive system that features high ultimate bond strength, very good high temperature, solvent resistance and very high shear holding power. Bond strength increases substantially with natural aging. 3M™ Adhesive 100 is well known in the industry for environmental and chemical resistance. For many applications, any one of the products in this grouping will perform satisfactorily when exposed to different chemicals or temperatures. The adhesive offers excellent bond to metal and high surface energy plastics and good temperature and chemical resistance.

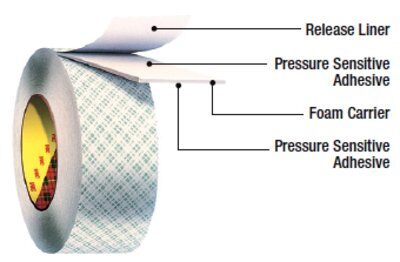

What is Double Coated Tape?

In general, double coated tape is composed of a paper, film, or tissue carrier that is coated on both sides with pressure sensitive adhesive. The adhesive is protected by a peel-away liner that can be removed at the time of application or left in place until the joining surfaces are ready to be attached. These tapes can be applied by hand or with a dispenser. Double coated tape dispensers are available in a variety of configurations ranging from manual to fully automatic. Applications for double coated tape are found in construction, fabrication, arts, and hobby.

Additional information

| Weight | 11.4 lbs |

|---|---|

| Length | |

| Units Per Case | |

| Adhesive Type | |

| Dimension 1 | |

| Double Sided Adhesive | |

| Liner Color | |

| Liner Thickness | |

| Liner Type | |

| Backing Material | |

| Color | |

| Length Metric | |

| Thickness | |

| Thickness Metric | |

| Width | |

| Width Metric | |

| Shelf Life | |

| Solvent Resistance | |

| Tape Type | |

| Temperature Resistance Initial | |

| Temperature Resistance Long Term | |

| Density |

![3m-double-coated-foam-tape-4016[1]](https://www.jamindustrialsupply.com/wp-content/uploads/2014/02/3m-double-coated-foam-tape-40161.jpg)