- Abrasives and Accessories

- Adhesives, Sealants and Accessories

- Cleaning Supplies and Equipment

- Drill Bits and Accessories

- Electrical Items

- Hardware and Fasteners

- Health and Safety

- Lubricants and Penetrants

- Manufacturers

- Masking Products

- Office Supplies

- Packaging and Shipping

- Paint Application Products

- Painting Equipment and Supplies

- Polishing and Buffing

- Roto Mold Fasteners

- Tapes, Films and Accessories

2-Step Paint Preparation in Metal Fabrication with 3M™

October 22, 2025

When it comes to metal fabrication, paint preparation is often one of the most time-consuming steps in the production process.

Whether you’re building machinery, components, or large assemblies, the surface finish you achieve before painting directly affects coating quality and durability. Yet many shops still deal with too many sanding steps, inconsistent finishes, and unnecessary exposure to vibration and dust.

These challenges add time and increase abrasive use, also making it harder to maintain consistent results from one operator to the next.

For the best surface prep before painting, your processes need to be smarter and involve the right paint preparation supplies.

Rethinking the Paint Preparation Process

3M’s two-step system is built around the principle that every stage of surface preparation should support the next. Instead of relying on multiple sanding or grinding passes, the company designed a simplified sequence that achieves the same results in half the time.

This process uses two main technologies, namely:

- 3M™ Cubitron™ abrasives for fast material removal

- 3M™ Scotch-Brite™ surface conditioning products for refined finishing.

Together, they reduce process steps, improve coating adhesion, and enhance operator comfort.

Step 1: Weld and Surface Grinding

The first stage involves removing welds, mill scale, and surface imperfections. In most operations, this is where bottlenecks form, especially when discs wear down unevenly or require frequent changes.

3M’s precision-shaped grain, featured in its Cubitron™ line, was designed to address this problem. Each grain is engineered to maintain a sharp cutting edge throughout its life, allowing the disc to cut cooler and faster while lasting longer.

For most fabrication environments, we recommend:

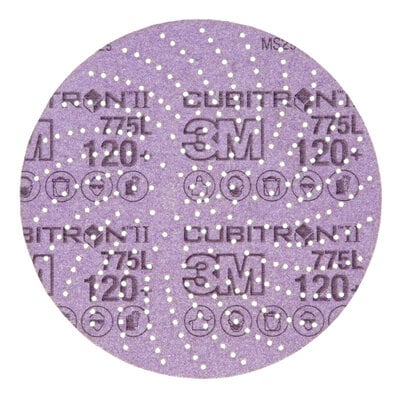

- 3M™ Xtract™ Cubitron™ II Film Disc 775L (120+, 6″): A high-efficiency sanding disc that captures up to 99 percent of dust and lasts up to four times longer than conventional abrasives. The film backing provides durability without compromising flexibility, making it ideal for both flat and curved surfaces.

- 3M™ Cubitron™ II Stikit™ Film Disc 775L (5″): A smaller option that works well for detail work and edge blending. The Stikit™ attachment system allows for quick changes, keeping your workflow consistent and efficient.

Both products deliver a steady cut rate, reduce operator fatigue, and help maintain consistent surface quality before the next step.

Step 2: Refining and Conditioning

After the grinding stage, the goal is to refine the surface to achieve a smooth, clean finish that will hold paint evenly. To achieve a uniform, paint-ready surface that improves coating adhesion and appearance, you need materials that remove light oxidation, fine scratches, and contaminants without overheating or altering the base metal.

For this, we recommend:

- 3M™ Scotch-Brite™ Edger Disc Pad 03648: A 5-inch pad that gives precise control when working around tight edges or small components.

- 3M™ Scotch-Brite™ Edger Disc Pad 09153: A 6-inch pad designed for larger areas, offering a balance between flexibility and coverage.

Using these products together ensures an even surface across both large panels and intricate parts.

Why the Two-Step Process Matters

This approach is effective because each stage complements the other. The Cubitron™ discs perform the heavy cutting work, while Scotch-Brite™ products deliver the refined finish that paint requires. The result is a complete surface preparation system that improves both quality and efficiency.

Key benefits include:

- Increased Productivity: Fewer steps mean faster completion times and reduced downtime for disc changes.

- Consistent Results: Precision-shaped grain ensures even wear and predictable performance across shifts.

- Improved Safety: Reduced vibration and advanced dust extraction create a cleaner, more comfortable workspace.

- Lower Total Cost: Longer-lasting abrasives minimize replacement frequency and lower the cost per finished part.

By focusing on the process rather than individual tools, you can achieve a measurable difference in throughput and quality.

Proven Results From Real Manufacturers

Across multiple industries, manufacturers have reported significant improvements after adopting this approach. Many have doubled their productivity while using fewer abrasives, saving both time and material costs. Others have seen better coating consistency and reduced rework due to more uniform finishes.

Besides measurable efficiency gains, these operations also benefit from cleaner workspaces and reduced operator strain, contributing to long-term improvements in safety and employee satisfaction.

Smooth and Streamlined Surface Prep With 3M™ Cubitron™ and Scotch Brite™

A smooth, paint-ready surface is the foundation of a quality finish. With 3M’s two-step paint preparation process, you can simplify your workflow, improve consistency, and create a safer, more efficient production environment.

At JAM Industrial Supply, we work with manufacturers to identify the right abrasive systems for their specific needs. By combining Cubitron™ grinding and Scotch-Brite™ finishing technologies, you can achieve faster turnaround times, lower costs, and a superior surface finish every time.

If your paint prep process takes too long or produces uneven results, it’s time to simplify. Find the right discs and pads for your operation and start improving paint preparation efficiency today. Need help finding the right product? Contact us today for assistance!