- Abrasives and Accessories

- Adhesives, Sealants and Accessories

- Cleaning Supplies and Equipment

- Drill Bits and Accessories

- Electrical Items

- Hardware and Fasteners

- Health and Safety

- Lubricants and Penetrants

- Manufacturers

- Masking Products

- Office Supplies

- Packaging and Shipping

- Paint Application Products

- Painting Equipment and Supplies

- Polishing and Buffing

- Roto Mold Fasteners

- Tapes, Films and Accessories

3M and GM Revolutionize Auto Paint Repair With Robotic Innovation

May 27, 2025

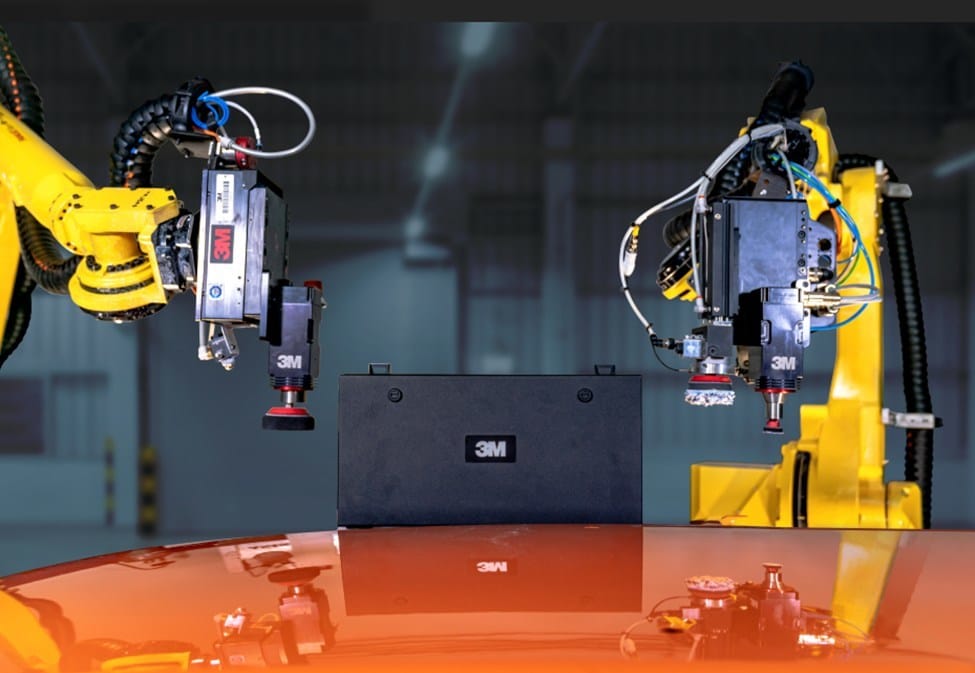

In a groundbreaking move shaking up the automotive manufacturing world, 3M and General Motors (GM) have collaborated to launch the first-ever robotic paint repair system on a moving assembly line.

This cutting-edge development is a milestone for the two industry giants and signals where the future of auto manufacturing is headed: toward smarter, more precise, and more efficient solutions.

As a 3M Strategic Distributor, JAM Industrial Supply shares these advancements and helps bring 3M’s technology and products directly to auto care professionals. Let’s take a closer look at this breakthrough and what it means for automakers, body shops, and everyone in between.

Automating the Final Frontier: Robotic Paint Perfection

In GM’s Spring Hill, Tennessee plant, where luxury Cadillac SUVs are built, 3M’s Finesse-it™ Robotic Paint Repair System has been deployed to automate topcoat paint repair, one of the most tedious and unpredictable parts of the car manufacturing process.

Here is what makes this system remarkable:

- Vision-Based Inspection: The vision system scans the vehicle from all angles to locate and categorize paint imperfections.

- Custom Repair Plans: The system determines a tailored repair plan for each car based on inspection data.

- Robotic Sanding and Polishing: 3M’s robotic arms, equipped with precision abrasives and polishers, fix those flaws as the car continues moving down the line.

Why This Innovation Matters

Traditionally, final-stage paint correction has been manual and labor-intensive, often requiring multiple layers of human assessment and touch-ups. This process is not just slow; it is also prone to inconsistencies.

As Ryan Odegaard, GM’s Director of Paint Polymers and Additive Manufacturing, put it, “If you have a customer-facing product, you have to make sure that that paint finish is perfect because it’s the first thing you see when you go into a dealership.”

By working with 3M, GM tackled a pain point shared across the auto industry: automating the last mile of perfection. The result? Increased efficiency, fewer errors, more consistent paint quality, and less rework and downtime.

The fact that this system works on a moving assembly line — streaming real-time data and dynamically adjusting robot movements every 10 milliseconds — is nothing short of extraordinary. The innovation is also a huge leap for other high-volume manufacturers considering automation for high-precision work.

What It Says About 3M

The partnership reinforces what many already know about 3M. The brand is a supplier and a solutions provider. To solve a uniquely complex, real-world hurdle, which the company has been doing since the 1900s, it combined three things:

- Decades of robotics and automation experience

- Legendary abrasive technology

- Smart process modeling and software engineering

As Marcus Pelletier, 3M’s Global R&D Director of Systems Development, said, “We don’t want to tackle the easy problems… We wanted to find the hard problems and showcase our capabilities and deliver that value…”

This mindset drives everything the brand rolls out, and it is why we promote the brand for every step of auto paint and repair.

JAM Industrial Supply: Paint Solutions for Every Auto Pro

You don’t have to be GM to benefit from 3M’s paint repair innovation. Whether you are an OEM manufacturer, a collision center, or a local auto body shop, JAM Industrial Supply carries 3M’s trusted offerings to help you deliver flawless finishes every day.

What if you are still doing paint repairs manually? No problem. Many body shops still do. The great news is that 3M’s innovations are scalable. You can implement the same abrasive, sanding, polishing, and prep technologies used by major OEMs without the robotics.

JAM Industrial Supply helps you access these products at competitive prices. Count on us for exclusive discounts, early access to new items, and personalized service you will not find with just any supplier. Even without full automation, you can still improve quality, reduce sanding time, lower material waste, and speed up turnaround times.

Let Us Bring the Future of Paint Repair to Your Shop

3M’s partnership with GM is a sign of what is coming. While robotics is not yet in your immediate future, you can still leverage the same technologies that power these systems through the high-performance 3M products available at JAM Industrial Supply.

We proudly serve professionals in the automotive industry and give our customers a real edge. We’re ready to hand you the tools you need to work smarter and guarantee excellent results. Call us at (330) 456-3000 or contact us online to discuss your needs.

Read the original article from 3M here.