Product Description

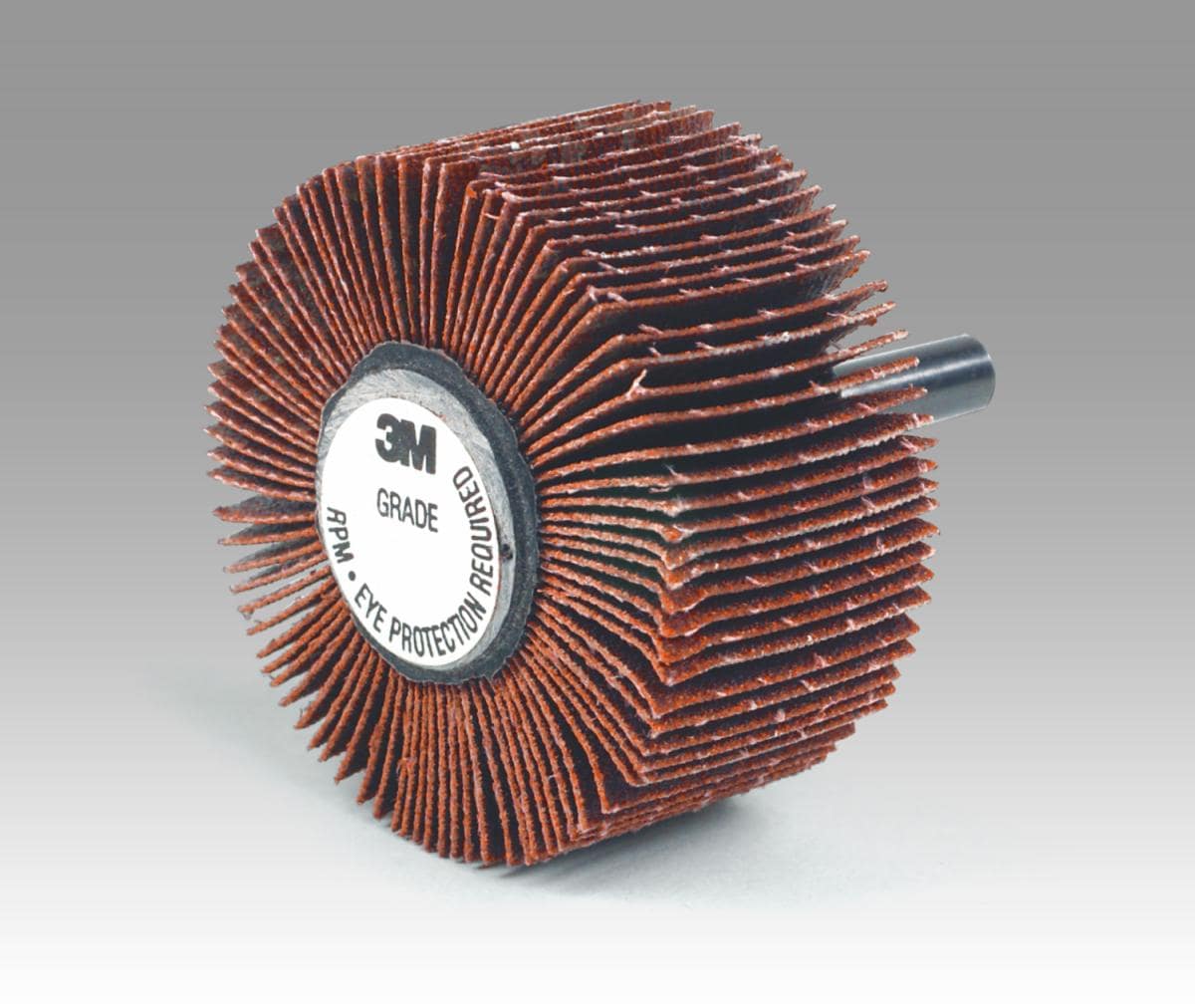

Flap Wheel 747D

- Abrasive flap design provides a soft and smooth cut on rounded or irregular surfaces

- Ceramic aluminum oxide blend offers excellent cut rate and life for better performance

- Includes a grind-aid to provide cooler running on stainless-steel and other metals

- Resin bonding resists thermal and chemical deterioration for extended wheel life

- X-weight cotton backing withstands aggressive sanding and grinding

Mixed Ceramic Abrasive

Each flap on the 3M Flap Wheel 747D is covered with a ceramic abrasive mix, which was designed using a proprietary process to enhance toughness and hardness of the grain. For increased performance, this mix features aluminum oxide blended with 3M ceramic grain to create a harder, longer-lasting abrasive. Perfect for light to moderate stock removal, ceramic abrasives are engineered to cut fast and handle intense heat and stress applications. Ceramic/aluminum oxide blend surpasses aluminum oxide abrasives in cut-rate and durability and makes it an excellent choice for moderate stock removal and surface preparation.

High Quality Construction

The abrasive mix is attached to a flexible cotton backing using a resin bond. This resin bonding material is specially designed to resist thermal and chemical deterioration, which can occur during high speed sanding. This bond is very hard which allows for faster cuts and a higher cut rate. This wheel also includes a grinding aid for cooler running on stainless steel. Each flap uses an X-weight cotton backing, which provides a tough, but flexible surface that bends to fit any work piece. As the wheel is used, the self-cutting flaps wear away to expose sharp, new abrasive material, assuring that surfaces are sanded consistently throughout the life of the wheel.

Flap Wheel Advantages

Coated abrasive flap wheels are the ideal choice for light grinding, blending, graining and scale removal on a variety of metals. The abrasive flaps offer a long lasting supply of fresh abrasives and a load resistant design. 3M flap wheels are available in both flange mounted and spindle mounted constructions with general purpose aluminum oxide or high performing 3M ceramic aluminum oxide blend abrasive grain.

For more information about Flap Wheel 747D, visit the official 3M website.

About JAM Industrial Supply of Ohio

Locally owned and operated in Canton, OH, JAM Industrial Supply, LLC has been a 3M Premier distributor and industrial supplier for over 20 years. With our vast network of vendors, we are able to supply the industry’s best products, information, delivery and prices to our customers.

Can’t find what you need? Contact us today for assistance.

Buying in bulk? Apply for special discounts on large quantity orders.

Additional information

| Unit of Measure | |

|---|---|

| Product Id | |

| Part Number | |

| UPC | |

| Per Case | |

| Weight | 0.616 lbs |

| Brand | |

| Center Hole Diameter | |

| Diameter | |

| Width | |

| Abrasive Material | Ceramic |

| Application | Finishing, Grinding |

| Backing Material | |

| Backing Weight | |

| Equipment - Machines | Inline Sanders, Manual Backstand, Die Grinders |

| Grit | 80 |

| Industries | Metalworking |

| Maximum Speed | 30000 rpm |

| Net Weight (Imperial) | 0.45 lb |

| Product Color | Orange |

| Product Form | Flap Wheel |

| Shank Diameter (Imperial) | 0.25 in |

| Shank Size | |

| Sub Applications | Setting the Grain, Refining, Blending, Descaling |

| Sub Industries | Metal Fabrication |

| Wheel Type | |

| Dimensions | 7.4 × 6 × 3.4 in |