Product Description

Additional information

| Per Case | |

|---|---|

| Weight | 6 lbs |

| Size | |

| Previous 3M Stock Number | |

| Attachment Type | |

| Backing Material | |

| Color | |

| Grade | |

| Mineral Type | |

| Per Roll |

Shop By Category

Shop Special SalesShop By Brand

Shop Special SalesBACK

CLOSE X

CATEGORIES

BACK

CLOSE X

BACK

CLOSE X

BACK

CLOSE X

Other Ways To Shop

BACK

CLOSE X

For Industrial Use Only. Estimated Lead Time Is 2 Working Days.

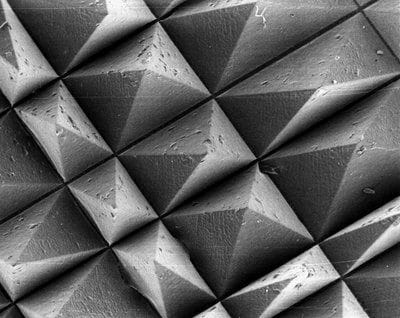

Film Disc Roll 466LA uses proprietary 3M microreplication technology, micron-graded silicon carbide particles are formed into tiny pyramids of abrasive mineral on a non-compressible 3-mil polyester film backing. More Info

3M™ Trizact™ Finesse-it™ Film Disc Roll 466LA, A7, 3 in x NH, Die 300V is available for purchase in increments of 1

3M™ Trizact™ Finesse-it™ Film Disc Roll 466LA uses proprietary 3M microreplication technology, micron-graded silicon carbide particles are formed into tiny pyramids of abrasive mineral on a non-compressible 3-mil polyester film backing.

Available in three grades — A3, A5, and A7 — 3M™ Trizact™ Finesse-it™ Film Disc Roll 466LA is the clearcoat spot repair disc used by automotive manufacturers worldwide. In convenient roll form, these discs are designed for quick access and attachment to rotary tools or orbital sanders.

While it breaks down faster than aluminum oxide, silicon carbide produces a brighter finish. It’s commonly used for defect repair on clear coats, paint and plastics, because it can effectively refine these surfaces without significantly gouging or damaging the workpiece.

Remove small defects with a 3M™ Trizact™ Finesse-it™ Film Disc Roll 466LA A5 disc. Sand in a circular motion, holding the pad flat to ensure a fine uniform finish.

3M™ Trizact™ structured abrasives are precisely shaped engineered composites evenly distributed and bonded to an abrasive backing. These extremely uniform abrasive structures can take the form of almost any three-dimensional geometric shape, including pyramids, hemispheres and cubes, designed to enhance grinding performance. While conventionally coated abrasives often have erratically spaced mineral, Trizact™ abrasives are identical in height and orientation, wearing just as uniformly. As they do so, fresh, sharp mineral is exposed to produce a consistent cut and a predictable, fine finish. Altogether, this means fewer rejects and less rework due to out of spec results. Ongoing sharp cutting action minimizes the need to incorporate other abrasives in the sequence, thereby reducing processing steps and enhancing productivity.

In addition to high-performance abrasives, 3M microreplication technology is also used in the manufacture of a variety of 3M products such as overhead projector lenses, reflective traffic signs and solar optical films. It’s science, making your world smoother and brighter.

Locally owned and operated in Canton, Ohio, JAM Industrial Supply, LLC has been a 3M Strategic Distributor and industrial supplier for over 20 years. With our vast network of vendors, we are able to supply the industry’s best products, information, delivery, and prices to our customers.

| Per Case | |

|---|---|

| Weight | 6 lbs |

| Size | |

| Previous 3M Stock Number | |

| Attachment Type | |

| Backing Material | |

| Color | |

| Grade | |

| Mineral Type | |

| Per Roll |