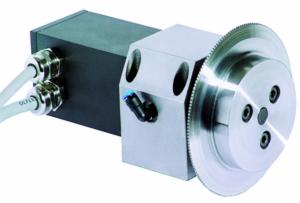

Product Description

Diamond and CBN Wheels and Tools

- Available in aluminum oxide and silicon carbide mineral

- Available in various dimensions, so operators can accommodate wheel size

- Available in various grades depending on the dressing stick dimensions

- For use on resinoid CBN and diamond superabrasive wheels

- Good multi-purpose dressing tool, especially for superabrasive wheels

Don’t Forget to Dress

3M offers a versatile line of dressing tools, each uniquely equipped to sharpen specific wheels. Ultimately, the dressing tool you select will be based on a variety of factors, including wheel type, size, mineral type and just how much buildup needs to be cleared from the wheel. 3M Dressing Stick is commonly used to dress Phenolic Resin, Polyimide Resin, and Hybrid bond superabrasive wheels.

The dressing stick comes in two minerals: aluminum oxide and silicon carbide. While other 3M dressing tools use diamond mineral, these two synthetic minerals are uniquely suited to tackle superabrasive wheels. The aluminum oxide dressing stick is commonly used on cubic boron nitride (CBN) wheels and the silicon carbide dressing stick is typically used on diamond wheels. 3M create this dressing stick in a variety of sizes and mineral grades, so operators can best match the right dressing stick to their application.

Help Wheels Live Longer

While truing is synonymous with profiling and helps restore the wheel’s original shape, dressing cleans the wheel’s surface by clearing away loaded material and removing worn and dull mineral and also exposes sharp mineral. Naturally, bond material and swarf build up on the wheel over time. Moreover, when a loaded wheel heats up, it can lead to glazing or smoothing of the wheel’s textured face. These issues highlight the importance of dressing; it will help your wheel run as intended.

In summary, truing and dressing are important maintenance processes required to keep expensive abrasive wheels cutting consistently. These applications help you extend the lifespan of your wheels and should be an integral part of any workshop that uses abrasive wheels regularly.

For more information about Diamond and CBN Wheels and Tools, visit the official 3M website.

About JAM Industrial Supply of Ohio

Locally owned and operated in Canton, OH, JAM Industrial Supply, LLC has been a 3M Premier distributor and industrial supplier for over 20 years. With our vast network of vendors, we are able to supply the industry’s best products, information, delivery and prices to our customers.

Can’t find what you need? Contact us today for assistance.

Buying in bulk? Apply for special discounts on large quantity orders.

Additional information

| Product Id | |

|---|---|

| Part Number | |

| UPC | |

| Weight | 0.061 lbs |

| Make to Order | |

| Brand | |

| Diamond Depth | 0.25 in |

| Length | |

| Thickness | |

| Abrasive Material | Aluminum Oxide |

| Application | Grinding |

| Grit | 150 |

| Industries | MRO, Precision Grinding & Finishing, General Industrial, Cutting Tool Manufacturing, Metalworking |

| Product Color | Gray |

| Product Form | Dressing & Truing |

| Sub Applications | Truing, Dressing |

| Sub Industries | Turbine Engines, Plating & Polishing, Metal Implants, Metal Fabrication, Plumbing Fixtures, Builders Hardware, Medical Instruments |