Product Description

Scotch-Brite Surface Conditioning Scrim Backed …

- ENHANCED CONFORMABILITY: Allows abrasive to stay in contact with complex-shaped parts in robotic processing

- EXTENDED OPERATING TIME: Reduced loading and heat build-up allow for longer use and consistent surface conditioning results

- IMPERFECTION REMOVAL: Eliminates surface imperfections, grind lines, mill marks, and other blemishes

- SUPERIOR FLEXIBILITY: Reinforced backing and nonwoven open web material offer excellent adaptability for detail work over contours and edges

- VERSATILE APPLICATIONS: Nonwoven surface conditioning belts are used for cleaning, blending, deburring, and finishing

A Versatile Abrasive: Scotch-Brite SC Surface Conditioning Belt work well to remove coarse grind lines, mill marks, or small burrs left by cutting tools or conventional abrasives. Abrasive belts come in many different widths and lengths and are used on a variety of different belt sanding tools for many different applications on both wood and metal. Ideal for Robotic Finishing: With a wide range of conformability options and high consistency, long-lasting Scotch-Brite industrial abrasives are a great option for robotic metal finishing. Scotch-Brite SC Surface Conditioning Belts can generate a spec-required, aesthetic finish when used in both manual and robotic processing.

Choose the Right Belt for You: At 3M 3M offer a broad selection of belts to fit most any industrial belt sander. Wide belt sanders are used for sanding and finishing large wood panels. Medium-width belts fit onto edge or portable belt sanders for sanding or blending wood pieces such as cabinet doors, and narrow belts are used with file tools in metalworking to access small areas or inside corners. Hard-Working Minerals: Aluminum Oxide and Silicon Carbide: 3M manufacture Scotch-Brite SC Surface Conditioning Belts with a choice of silicon carbide or aluminum oxide abrasive mineral. Silicon carbide is a synthetic mineral that is very sharp and commonly used for low-pressure applications such as paint prep and finishing.

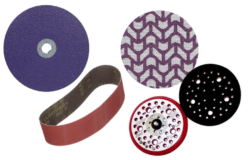

Aluminum oxide is a hard, blocky mineral that provides high cut-rate and long life. While silicon carbide breaks down faster than aluminum oxide, it produces a finer finish. An Alternative for Wheels and Discs: Belt sanders are used for rapid grinding, sanding and finishing on a variety of surfaces. Depending on the material being worked, sanding wheels and discs may clog, quickly making them less efficient, while belt sanders continue to sand without clogging because small grooves in the abrasive belt open as they go around the arc of the drive wheel.

For more information about Scotch-Brite Surface Conditioning Scrim Backed Belt, visit the official 3M website.

About JAM Industrial Supply of Ohio

Locally owned and operated in Canton, OH, JAM Industrial Supply, LLC has been a 3M Premier distributor and industrial supplier for over 20 years. With our vast network of vendors, we are able to supply the industry’s best products, information, delivery and prices to our customers.

Can’t find what you need? Contact us today for assistance.

Buying in bulk? Apply for special discounts on large quantity orders.

Additional information

| Unit of Measure | |

|---|---|

| Product Id | |

| Part Number | |

| UPC | |

| Per Case | |

| Weight | 0.647 lbs |

| Make to Order | |

| Brand | |

| Length | |

| Width | |

| Abrasive Material | Aluminum Oxide |

| Application | Grinding, Surface Preparation, Cleaning, Finishing, Deburring |

| Backing Material | |

| Bond Type | Resin |

| Equipment - Machines | File Belt Sanders, Manual Backstand, Inline Sanders |

| Grade | |

| Industries | General Industrial, Marine, Metalworking, MRO, Transportation & Heavy Equipment |

| Low Stretch | No |

| Product Form | Belt |

| Wet or Dry | Dry |

| Dimensions | 8.6 × 8.5 × 6.7 in |