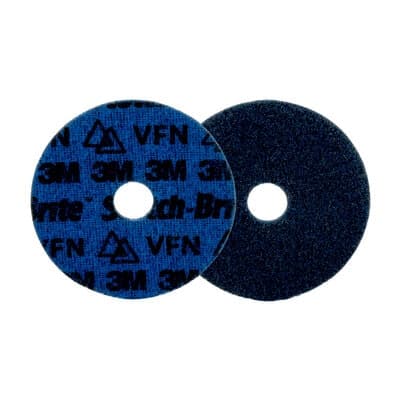

Product Description

Advantages of Scotch-Brite™ Precision Surface Conditioning Disc

- A NEW LEVEL OF MULTI-PURPOSE PRODUCTIVITY: Expanded grade range allows these new discs to cover blending, cleaning, deburring, finishing, grinding, polishing, radiusing and refining applications

- UPGRADED FOR HIGH PERFORMANCE: Built with 3M Precision-Shaped grain for increased cut-rate without sacrificing finish

- WORKS ON A RANGE OF METALS: Great for use on aluminum and soft metals, carbon steel, stainless steel and more

- QUICK AND EASY ATTACHMENT: Hook and loop backing makes for easy disc attachment, removal and re-attachment in multi-step processes

- CONFORMABILITY WITHOUT COMPROMISE: 3M Precision-Shaped Grain delivers an aggressive cut while conformable nonwoven web helps protect against gouging

- TWO INNOVATIVE TECHNOLOGIES IN ONE DISC: Scotch-Brite™ nonwoven fibers combined with 3M Precision-Shaped Grain deliver improved performance over traditional surface conditioning discs

- AVAILABLE IN A RANGE OF GRADES: Choose from Very Fine (VFN), Fine (FN), Medium (MED), Coarse (CRS) and Extra Coarse (XCRS) to fit your application needs

Scotch-Brite™ Precision Surface Conditioning Discs, 3M’s reformulated multi-purpose discs, feature 3M Precision-Shaped Grain technology incorporated into the nonwoven web, bringing a new level of productivity and abrasive life to the Scotch-Brite™ lineup.

Scotch-Brite™ Precision Surface Conditioning Discs, the newest addition to the Scotch-Brite™ lineup, promise increased cutting speed and longer abrasive life. By combining two flagship 3M technologies — nonwoven fibre and ceramic 3M Precision-Shaped Grain — you can get the ideal finish, faster. These discs come in brighter, more vivid colors to make identification easier. The grade range has also been expanded to include Fine and Extra Coarse offerings. 3M designs these premium multi-purpose discs to streamline surface conditioning processes including cleaning, blending, deburring and finishing. Applications range from coating and corrosion removal to refining and post-cast processing.

Additional information

| Weight | 2.5 lbs |

|---|---|

| Product Id | |

| Part Number | |

| UPC | |

| Per Case | |

| Brand | |

| Attachment Type | |

| Make to Order |